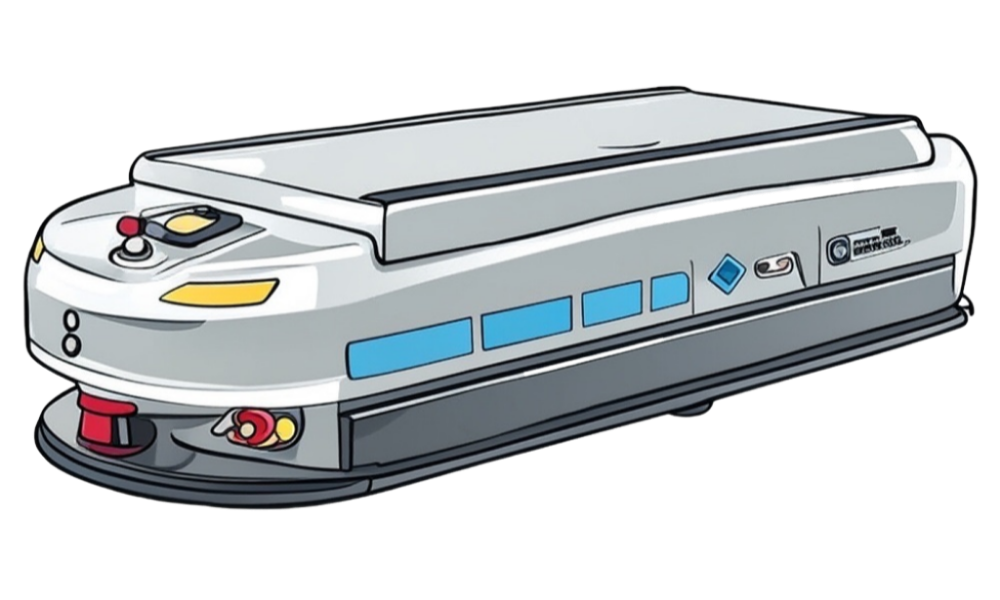

Revolutionise Your Healthcare Logistics with our Autonomous Guided Vehicle (AGV)

Improve your hospital efficiency with food, linen, supplies and waste delivery

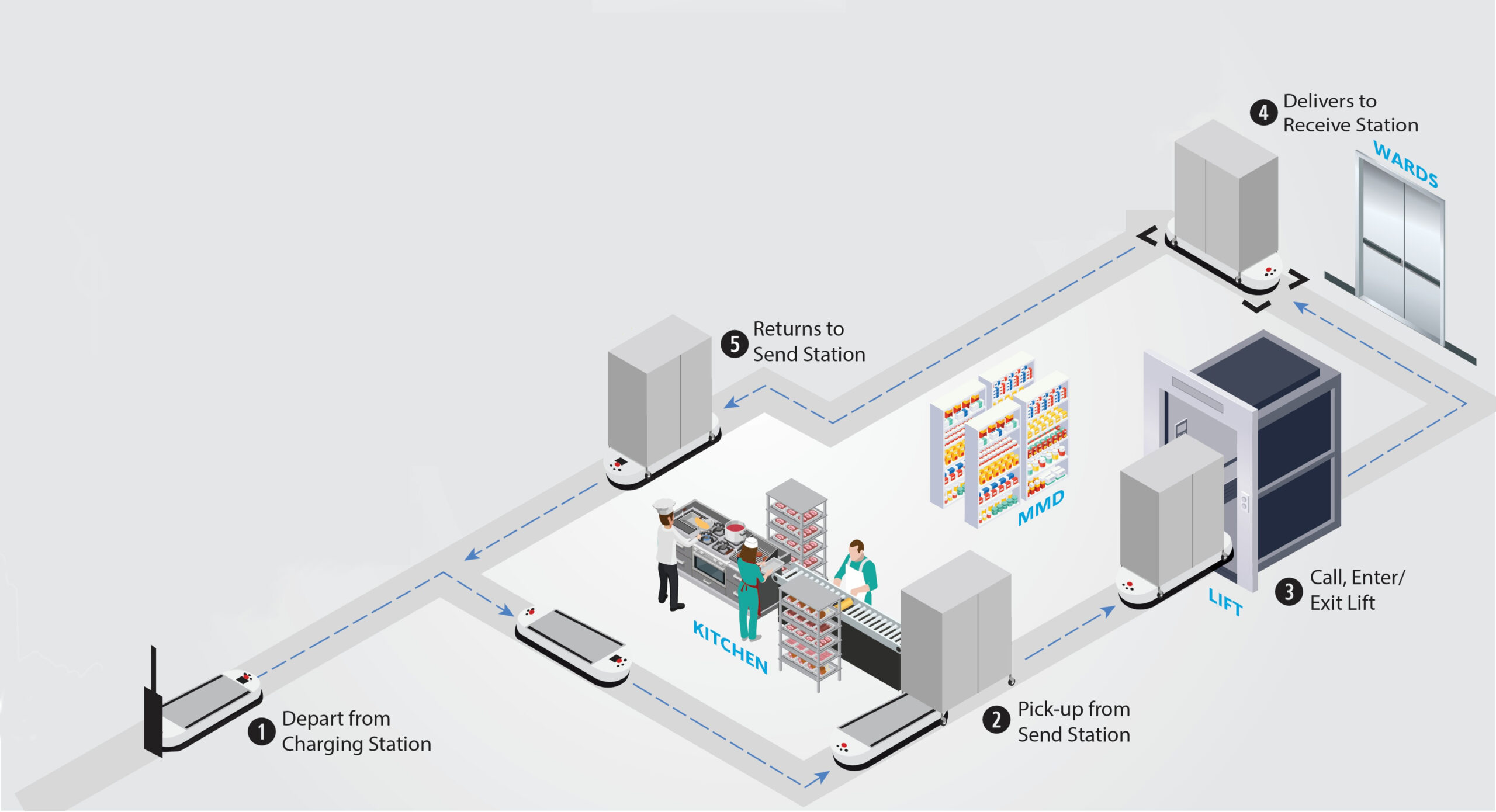

How does our AGV help streamline your operations?

Implementing our Automated Guided Vehicles (AGVs) in hospitals revolutionises logistics by automating the tedious task of trolley pushing, freeing up valuable staff time for more productive, patient-focused activities such as direct care, administrative duties, or skill development. This not only boosts operational efficiency by ensuring timely deliveries of food, linen, supplies, and waste, but also reduces physical strain on employees, aligning with Australia’s Work Health and Safety regulations under the Work Health and Safety Act 2011 to minimise workplace injuries and fatigue.

Additionally, AGVs enhance reliability with 24/7 availability, improve hygiene by minimising human contact with trolleys as well as minimising wheel contact with the floors (through it’s lifting capability), and supports cost savings through optimised routes and reduced labor expenses, ultimately elevating overall hospital performance and patient satisfaction.

View our Transcar K2 AGV in Action

Roles of our AGV in the Hospital

Our AGV can transform your hospital logistics by efficiently transporting food, linen, supplies, and waste across departments, ensuring timely delivery without disrupting staff workflows.

AGVs navigate pre-defined routes, integrating seamlessly with lift systems to minimize bottlenecks, while their 24/7 availability supports critical operations such as the following:

Meal Delivery

Linen Delivery

Supplies Delivery

Waste Delivery

Our AGV Statistics

995+

AGVs globally

47+

Hospitals globally leveraging our AGVs

490kg+

Supported by one AGV

1

Workers supported by one AGV

READ THE ARTICLE

OTSAW Expands into Australia and New Zealand with OTSLE as Key Distribution Partner for Transcar AGV

Simplify your day-to-day process with our Key Benefits

A typical 800 Bed Hospital

600 Trips daily

Requires the effort of pushing the cart across the hospital 600 times in a single day.

Requiring 240km of cumulative walking

The journey can see a combined distance of 240km.

180 Tonnes in Weight

Requiring a total lifting capacity of 180 tonnes.

Safety Features of our AGV

With obstacle detection sensors for automatic slowdown or stop, and a design without video recording to protect privacy, ensuring a secure environment for hospital staff and patients

Laser Scanner

Tricycle Drive System

E-stop

Ultrasonic Sensors

Bumper Strips

Data Recording and Location Tracking

Supporting our Clients

Our AGV is designed and engineered in Germany. It is built to enhance hospital operations by automating the delivery of meals, medical supplies, linen and waste. By seamlessly handling routine, time-consuming tasks, our AGVs free up skilled staff to focus on patient care while improving speed, safety, and overall operational efficiency.